There was a retail store chain in North America which some of you may have heard of known as SEARS. (There may still be some Sears outlets around, but they are few and far between any more.)

Sears is a department store selling all kinds of products from all kinds of manufacturers. They also have products manufactured with their own brand name for sale in their own stores and online. Craftsman compressors is one of those products.

The Craftsman brand is the name of their broad range of tools and workshop accessories as well, but on this page, we’re only concerned about the Craftsman compressors.

Over the many years the Craftsman /Sears compressor brand has been available, the actual air compressors have been made for Sears by a range of manufacturers. Therefore, a model number available in 2014 may not have been made by the same company with that same model number available in earlier years. Or, there are so many model numbers, it’s hard to find specific information about that one.

You can ask your own questions about Craftsman / Sears compressors by using the form below. If you do post a question, please include at least one photo of your compressor. More photos are better if you want to focus in on the problem area on that compressor.

Please only post questions and comments about Craftsman / Sears air compressors on this page if you would be so kind. General questions can be posted elsewhere on this site.

More pages with questions and information about Craftsman air compressors:

- Pressure switch on my Sears compressor 919.195411 is shot

- Craftsman 919.195410 compressor may not have enough flow

- Sears / Craftsman 30 gallon compressor will not start

- Craftsman air compressor will not start

- Craftsman unloader valve is not working

- 33 gallon Craftsman compressor keeps tripping the breaker

- Can I get get 80 PSI on a Craftsman Air Compressor Model 106.174540?

- 7 year old Craftsman 26 gallon 1.6 HP 160 PSI Air Compressor loses about 40 PSI of pressure a day.

What is the rpm that the 1hp 919.174212 dual piston pumps should be running at? Trying to figure out size of pulley to put on the 3450rpm motor to get the right rpm spinning on the pump.. guessing like 850 rpm on pump.. right?

I have a craftsman model 919.16726 air compressor. The pump shaft sheared off so suspect the pump is also fouled. I cannot find parts so was also looking to just update/ upgrade to a newer pump. I’d like to re-use the motor if possible due to cost but will replace both if no other option.

Hi. I have a Craftsman model 919.167600 1.6hp 26gal that is about 15-20 years old. I only use it occasionally but up until now without issue. I was using it to blow out sprinkler system lines and came in to it shut off. It actually tripped the gfci it was plugged into. Never an issue before. Now when I reset the gfci, it trips it again right away. I can hear the motor turn over and then it’s tripped. Research would point to the capacitor, but I am not seeing one on this model. I tried plugging into a different circuit and same issue. Also tried bypassing pressure switch and still the same. Any suggestions would be appreciated. Is the motor just shot? Is it time to buy a new one? Thanks

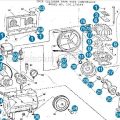

I have a Craftsman oil lubricated, single stage, horizontal portable air compressor, Model No. 919.195412. Apparently over time and vibration the parts which comprise the motor hold down plate have been lost. The only parts remaining are the 5/16” wing nut and rubber/metal washer. I am currently allowing the weight of the motor to act as the belt tensioner but, expect that is too heavy and may prematurely wear the pump bearing. The exploded parts diagram is not exactly set up like my compressor. Mine does not have the highlighted metal plate shown in the parts diagram, attached to the tank (photo attached). What parts am I missing and how att the arranged?

Is there a replacement fan kk-5018 for a Craftsman air compressor anything interchange?

I have a 33 gallon upright Craftsman 919.167320 and am in the process of replacing both the start and run capacitors due to the unit tripping the circuit breaker… My issue is where do the wires connect to the 3-terminal run cap? (Start cap is no problem.) The original run cap has no identification for the terminals, whereas the new one has C, FAN, and HERM. …I have red and brown wires coming from the motor, and another red which connects to the start cap through the centrifugal switch. Thanks!

Ok… It turns out that the run capacitor I bought was an HVAC dual run capacitor, which the post “HERM” is meant to supply the compressor motor voltage, and “FAN” is meant to supply voltage to the fan motor… As it turns out, this capacitor will still work just fine if wired as follows:

Start capacitor: black wire from motor to one post, and black wire from centrifugal switch to the other post. (AC capacitors are not pole sensitive.)

Run capacitor: red wire from centrifugal switch to “C” post (input power), and both the red and brown wires from the motor to the “HERM” post.

It starts and runs like a champ! …but now I’m faced with the issue of the pressure topping out at 80 psi with the motor and compressor still spinning like a top! 🙄

…the struggle continues…

Which wires go where yes I only know there’s two a red and a purple but I don’t know where they connect onto the capacitor please help model number 919.167310 Craftsman 30 gal 6 hp

I have an older Craftsman 919165050 and the Eccentric Bearing is broken, which they don’t make anymore. Can I and is there a replacement pump I can put on the tank or just trash this and get a new compressor?

Jesse, my thoughts are you can certainly reuse the tank. This page on this website can help (click here).

I have a Sears craftsmen compressor that runs and builders pressure but does not shut off

Sure Paul. This page and others on this site will help: http://fix-my-compressor.com/new-pressure-switch-and-still-the-air-compressor-will-not-stop/

Use the search box top right on any page to find more if you need it.

Just bought my Craftsman 919-195400 from a neighbor. It is a 6HP 110v and 220V.

Hasn’t run in years, so I’ll check the oil and clean the filter. Eventually change the oil too. Maybe a new belt.

Can I just change it over to 120 by changing the plug. What about the fuse?

What else should I look for? Drain the tank. I always used a water catch valve.

Thanks in advance for your ideas.

.

No. Changing the plug by itself won’t do it. You need to change the wiring in the motor as well. Open the motor plate and have a look at the wiring diagram for guidance, and if you browse “convert electric motor 220 to 120” you’ll find lots of wiring help. Not much point in reiterating it here.

One last note, if your pump is truly 6HP, I suspect it will not run satisfactorily on 110.

I have an OLD CRAFTSMAN COMPRESSOR 35+ years old. Still running but it is showing it’s age in loss of air volume. Upon draining the oil and replacing the 1×5 inch filter on top of the Engine I was unable to find any part numbers. All I have is a barely readable “use 20w…….. I can’t find 20w oil. I do have 30w non-detergent and am a little reluctant to us this.

What oil is best in today’s market???

You should be able to use SAE 30 NON-DETERGENT oil instead, particularly if the location is heated. It’s a higher viscosity oil, but not so good for colder locations.

my compressor will be in a unheated barn. Should I find a good compressor oil.

thanks.

bill

You’ll want to find a 10 weight non-detergent then. Yup, a good compressor oil is the right one to use, but I’m a bit concerned about the compressor not being able to start against sluggish oil if the weather is too cold. But, if you can’t find it, trial and error. Just make sure it’s detergent free, and if it says compressor lubricating oil, so much the better.

If the oil is not viscous as higher weight numbers are, running the compressor too long and overheating it a bit might be an issue with lower weight oils too.

Sorry I cannot be any more specific than that.

I have a 6HP 33 gallon Craftsman air compressor that won’t build pressure past 20 PSI. I’ve replaced and checked everything outside the pump. Before I go any further, and ideas where to start or what might be the issue?

Hi David. I took the time to retype your comment as comments in “all caps” are generally perceived as negative.

When you checked everything outside the pump I presume that no issues were found. That being said, this compressor appears to have a complete plastic cover of the motor and pump. Since I cannot see what the pump looks like, and could find no info about that on line, the symptom suggests that the problem could be a failed intake valve, a failed pressure valve, or a gasket failure in the pump. All of these issues are covered on the pages in this site. Visit this link and scroll down to the section about Compressor Will Not Stop / Run issues for pages of use.

Hello, I have a 5HP 25 Gallon Craftsman Compressor that is well over 25 years old. It still works but I was concerned that the tank may be too old and I’m afraid of it bursting. Is that possible? Can I get a replacement?

It makes sense to be concerned about the tank. If the tank has been stored with water in it, or if the tank hasn’t been drained regularly, there is possible rusting. It often occurs along the bottom of the tank where water would have been sitting, and that’s often the tank weld line as well. Put a little air (20 PSI or so) into the tank, and open the drain all the way. What comes out. If it’s dirty, rusty colored water, you may have an issue.

The only sure test is a hydrostatic test, and that will cost a lot, maybe as much as a new tank.

If the tank has been drained regularly, with the tank empty, use a rubber mallet and hit the tank all along the weldments, and along the lowest parts of the tank where water might have settled. Not too hard, but hard enough to determine if there is a rust-weak spot.

Another I’ve heard of but not tried is to fill the tank with water, and use a hand pump, like a grease gun, to inject more water into the tank to see if there is a weak spot.

You can dissamble the tank from the pump and using lights on extensions to try and see inside.

All of these are cumbersome and could be expensive. Yup, you can replace the tank. As long as you can attach the pump and motor to the new tank, with the same connections of line to the tank and pressure switch access, use any tank you wish.

Let us know how it turned out in a comment here if you have a minute.

Hello I have a Craftsman 919.727321 that is noisy and taking a long time to build up air, I need a compressor rebuild kit, do they still sell them? I can’t find the right one.

Thank you

Joe

I think this compressor is way more than a decade old… Yes? Unfortunately, there may have been many different manufacturers private-labelling Sears Craftsman air compressors over the years, and for compressors this old, no one is stocking parts that I can find on line anywhere. Sorry about that.

Well, I have an old Craftsman 919174212 compressor that works great eccept the pressure switch needs replacing. They don’t make that part any more. It does not have an unloader system. Question will a switch with an unloader still work on a machine that does not have that system? It looks like without the unloader hooked up the switch should still do its job. Also If that is the case what switch do you recommend that will fit in the space provided. I’m lookin at the single port Lefoo

I have a craftsman 919176320, the pressure switch went out, can you tell me where I can find replacement

David, from what I’ve been able to find, this compressor has an upper pressure of 100 PSI when it’s building air. That being the case, any pressure switch you select must have a cut out pressure of 100 PSI, or be adjustable so that you can dial the cut out to that maximum pressure.

If there is no unloader now, and I couldn’t find a photo clear enough to double check, and you select a switch that has an unloader valve on the side or internal to it, not connecting an unloader air tube to that will not affect the primary function of the switch which is to turn the compressor on and off depending on the pressure in the tank.

You want to make sure the voltage is the same as well.

As long as the pressure switch you choose can be wired the same way as the old, and you can plumb air into the main port of the switch, then viruatlly any off brand should work.

Photo: mastertoolrepair.com

Thanks,, the old relief valve was rated at 125(stamped in the side of the valve). I’ve always run it to cut out at 110psi and cut on at 90. As a custom picture framer, I operate a AMP v-nailer , an Senco pinner(nail gun) and a wizard cmc mat cutter and all work well with this set up. It started staying on sporadically and tripping the relief valve. Ultimately it just ran continuously. I have been turning it on and off manually in the interim ( pain in the ,,,,,,) I replaced the valve, the gauge and now the switch. Thanks for your input

Most welcome, David. Glad we could be of help.

Sluggish at build up to cut out and sluggish at cut in after drain down then blow breaker. Drain tank results in crisp start and run up to approx 90 lbs, then sluggish condition result up to 125lbs and cut out. New 5hp compressor. New motor 5hp dual stage 3400rpm. 5in single pulley on motor 14.5 on compressor. New regulator, new unloader value at tank. New start up capacitor and new over size run capacitor. 220 power – direct wired to 30 amp fuze. Dedicated line.

Sear Craftsman 60 gal tank. Not sure what to chk next. With the exception of the tank. All parts are new. Is it the combination. I also checked/clean the centrifugal starter capacitors at the end of the motor.

The symptoms suggest that the motor is lagging due to pressure buildup creating a higher load or there may be an electrical issue. Don’t know if this compressor has a starter, but I’d check a couple of things before looking for a bum valve in the pump. Consider having the wiring checked by an electrician, and even though the motor is new, check the start capacitor too.

I believe the pressure gauge is frozen, or maybe there is some trash in it. I looked for the part, and the manufacturer does not make it anymore. So I am wondering if this part is fixable, or if there is another route I can take to get my compessor up and running again.

Craftsman model # 919.195413

Ryan, the regulator and gauges are all available after market, and not that expensive. Google 1/8″ regulator to find sources. They typically come with the gauge. Should cost around $15 or so.

I have a Craftsman 919.184192 60 gallon compressor that loses oil into the tank. I’ve changed the rings and the reed valves with no improvement. Any suggestions?

Thanks,

Ben

Hi Ben. Where is the oil coming from? Presumably the oil has to be wicking up from the oil sump and into the air stream in order for it to get back into the tank unless you somehow have back flow from an oil source downstream from the compressor.

If it’s coming from the oil sump it suggests that there may have been an over-fill of oil in the recent past. Possible?

If no over-fill of oil, then it has to be coming past the piston rings into the compression chamber, and then being pushed back into the tank via the compression stroke.

Therefore, the replacement job done may be suspect.

It’s coming from the sump. I’m having to add more oil monthly. Can you tell me if the chamfered side of the oil rings is supposed to be up or down? I’m sure I replaced them the same direction the old ones were but old ones could have been installed wrong.

Thanks again,

Ben

Anybody know if the chamfered side of the oil rings should be installed up or down?

Ben, we don’t have specific knowledge about this ring on this compressor, but we do know that typically a chamfered piston ring has the chamfer on the back side so that pressure can help the ring seal against the piston wall. Hope this helps. Cheers.

I have 921.169130 with a mfg date of 5/13 SN 0020911. I’m pretty sure one or both of the capacitors are bad. Sears says these parts are no longer available. I purchased 2 capacitors (relatively inexpensive) that matched the uF ratings and installed them but they didn’t work.

I’m hell bent now on salvaging this compressor and pump by installing a new motor with capacitors already installed. Specs say it is a 1.5hp.

Any suggestions or assistance you can provide on where I can find a replacement motor would be appreciated before i spend more than what a new one costs.

Thanks Much

Mike

No idea where you are, or what sources you have. As long as the new motor fits, shaft diameter, mounting and as long as the rpm is the same, then any motor will work. I cannot be specific as to a source, sorry.

I need a motor and multi rib pulley for this compressor please

What compressor? Model number? Add a photo or two.

You do know that this is a peer to peer self help site for folks with compressor issues, and that we don’t sell parts?

Yes I know. Thank you. I put an image here, but it did not stick. I’ll try again

I have checked the upload system a number of times and haven’t had any issue with uploading photos. I am sorry that you are experiencing this. Can you tell me what you mean by “it didn’t stick”? Thanks.

I resized and posted the image, but it is not here apparently.

I’ve checked again. The site allows images of virtually any kind to be uploaded. I did note that the upload size was limited to 2 MB. I have now made the 5 MB. I suspect the issue is the your photo, if taken by a phone on high resolution, may exceed 2 MB is size. Now that I’ve changed the upload size, care to try again? Sorry about the problems.

I have a Craftsman 919.152830 compressor that has a broken pressure switch (I know it is broken because I was clumsy and broke it myself). I also have a new check valve on order (this was the real problem before I broke the switch). Sears did tell me that my compressor is a 1990 model.

What compressor pressure switch do I need or what will work?

Thanks!

http://fix-my-compressor.com/buying-a-new-replacement-pressure-switch/

I have a craftsman 30 gallon air compressor electric motor that has a bad bearing. Is there a replacement bearing ,or is there a replacement motor?

Bearings are typically made by a few companies and sold to “manufacturers” of equipment world-wide. Is the one in your Craftsman compressor unique? I’d suspect not. If you can pull the bearing, measure all dimensions and Google “replacement electric motor bearings”. I’d be surprised if you cannot get one after-market.

I have a Craftsman 33 Gal 6hp model 167340. pressure drops to 80lbs and stays there! check valve is new, took line off of the check valve to pressure switch, no leak. sprayed all connections, no leak. no pin holes on tank. pressure switch diaphragm is in great shape, but can it still leak there?

Are you saying that the pressure drops when using air, to 80 PSI, and then, with the compressor still running, the pressure in the tank stays there?

What is the normal cut in and cut out pressure, and how long has this issue been going on with your Craftsman compressor, Bob?

What is proper way to install a new plastic motor cooling fan on the motor shaft? I am working on a craftsman oil free air compressor? Do I heat the fan in boiling water to expand the hole in the fan or what. I don’t want to break the fan. thanks for help

Hey Lonnie, knowing the model and part number would make being more specific easier, perhaps. Is the shaft diameter really that small on the fan. Got the right fan for sure. Before heating the fan, maybe try a little grease / oil?

Willyr Thanks for your quick response. I ended up simply tapping gently with rubber mallet and got

it on.

i have a craftsman 919.175260 compressor that will pump up to around 40 lbs and then starts struggling to go further..i have replaced the pressure switch and check valve. any help would be great

Assuming no mechanical issues binding the pump, consider checking the motor capacitors. There is a page about how to do this linked from the troubleshooting page on this site.

I have a craftsman professional 25 gal 175 psi model:919.167783.

After fumbling with the intake and discharge lines and having to replace the aluminum line with a high pressure/heat freight truck plastic line, I found the pressure switch to be leaking at the port where it connects to the copper check valve.

Ultimately, I changed out the pressure switch and check valve for brand new parts, but still cannot get the tank to build pressure and still experience leaking at the same connection on the pressure switch.

It seemed to work for a while when I swapped the old check valve with one from another compressor, but that setup included a bushing with a small hole in the side 3/8 input and a tee above it that ran one side to the pump and the other to the pressure switch.

When I used the new parts and original setup, it went back to having the old problem again. I don’t want it to just work. I want to understand why the friggen thing does or doesn’t work. Please save me from my mounting frustrations.

Your post was moved to the Craftsman page, David.

If I understand correctly, you are exasperated by the fact that, with pressure in the tank, air continues to leak from the pressure switch regardless of what you’ve done to remedy that… yes?

If so, then a simple solution may be to check that the tank check valve, the device with the sole purpose of keeping air in the tank and stopping that air from flowing back out of the tank and out the unloader valve which is commonly found in or on the pressure switch to see if it actually is sealing air in the tank, or if it is leaking.

More on that here: http://fix-my-compressor.com/compressor-always-leaking-air/

It leaks air continually, from start and after I shut it off. The check valve and pressure switch are both brand new. The check valve SEEMS to cover the openings on the stem in closed position and the spring retracts and exposes the holes when depressed. I don’t know how to test the pressure switch diaphragm. But I suspect it to be in good shape. Both parts were purchased within the last week.

Hi David… let me ask something. If air is leaking from the compressor when the compressor is off, where is that air coming from? It has to be the tank, yes? If it’s the tank, and air is leaking on the compressor, not out of the air line coupler, then it has to be flowing back upstream past the tank check valve. If it is doing that, the tank check valve must be letting that air go by, and if that’s happening, the tank check valve is not working.

I suppose that’s the only thing it could be. It’s just a new part and the valve’s venting at the base seems to be covered in the closed position and uncovered in the open position, but maybe there’s a small leak that is imperceptible by me.

Thank you for your time.

Right, the unloader is closed when the compressor is running, and open when the compressor is stopped. The bulk of the air loss then will be when the compressor is stopped, if the tank check valve is leaking.

Craftsman compressor 921.153101, starts and stops then starts and stops,etc., etc. Will not stay running long enough to even put any air in tank. Appreciate any assistance. BTW, in checking the pressure switch, the “contacts” still touch even when the motor stops, so guessing probably not a switch problem. thanks

Good the switch contacts are touching when there is a call for air, Mike. Can you meter it to be sure that there is current flowing?

If so, when the compressor stops, is there power flowing across the switch then? If so, the problem is likely capacitor or motor related. Please advise.

I have craftsman #919.165230 and after a days work my compressor loses air in tank and I cannot seem to find out where the air is leaking from

Richard, that’s a classic symptom of a failing tank check valve. Dump all the air with the compressor off, pull the fitting where the line from the pump enters the tank, and there you’ll find the tank check valve. Clean it or replace it and that should likely solve the problem.

I have a craftsman 1.5hp 2 gal compressor and it reaches 25 psi and will not increase although the pump is still running, I have stripped the pump apart all gaskets and reed valves are ok. the piston compression rings are fine.

I have air pulling in at the intake and I cannot block the flow on the output, I have found the unloader vavle loose at the regulator. as this is my first regulator I am unsure if this is meant to be loose?

I am unsure what else can be the problem?

Please add a comment with a photo of the unloader valve at the regulator. I’m afraid I don’t know of any unloader valves on regulators, only on pressure switches.

Sorry, it is on the pressure switch not the regulator! my error, I tightened it up and it now reaches full pressure.

Once the pressure drops and the switch engages the motor hums and doesn’t come on (heats up).

I know this is one of the capacitors and I am going to guess the start cap. both caps on the motor are 15Uf so I am unsure which one is what and am wondering should they be the same?

Hello again, Jack.

If the caps are OEM equipment, then they are correct. I’d only be concerned about them being the same if somewhere along the line they were changed out and an error might have been made.

See the page on checking the caps, and check both. Let us know what you found if you would.

before moving onto the caps I replaced the pressure switch, it charges to full pressure still and again doesnt start when the tank has 120psi.

when I undid and redid the unloader tube from the top of the check valve the compressor can start again. This implies that there is air above the piston but it should have a brand new unloader valve inside the switch? am I on the right lines?

If air is trapped over the piston Jak, then that may be adding too much load.

You replaced the pressure switch. The unloader tube runs from the tank check valve fitting over to the unloader? If so, when the pressure switch trips to off, the unloader should open, and any air in that line, and in the line up to the piston, should vent. If that’s not happening, then there’s an issue with the line being plugged or the unloader not working as it should.

Any way you can get close enough to feel air coming out of the pressure switch when the compressor stops?

it vents, you hear the big hiss but it doesnt seem to vent it all and like you said the motor then has too much load?

what can i do about that if its had a new pressure switch and unloader valve

If you hear a hiss, Jak, then the unloader valve is open to vent. Unless, for some reason, the unloader is closing again (doubtful if the compressor is off which means the switch has tripped), then it pretty much has to be a weak start cap, unless there’s an actual motor issue.

Time to check the cap, I think.

OK so tested the caps, they are wired in parallel, each one is 15Uf so and read 29.8MFD so within the 5%.

now I am really confused?

So am I. If there are two capacitors on an AC motor, I don’t believe they are installed parallel. One will be start, the other run I expect. Test them separately if you would to see if both are really OK.

So I took a picture, each cap is joined together and and then plugged into the motor and the motor only has 2 cables coming from it

Jak, I know you are in the UK, and voltages etc. are a bit different there. I can only relate to my north american experience, and limited electrical background. The thing is, if the unloader stays open, and the caps are good, then it’s got to be the motor, yes? That means a motor test shop I’m afraid.

that was my deduction, electrically my knowledge is quite good as im an electrician its the compressor bit thats getting me.

I deducted that it must be the motor but now I am requestioning the unloader valve, if it stays open why do i have air above the piston?

could it be the check valve?

If the unloader valve is open, then unless a gasket or something has shifted in the pump head (unlikely) then there should not be air over the piston. Even if the tank check valve is leaking, that air would bleed out the unloader valve as well.

If air is trapped over the piston and the compressor is off, then the unloader valve must be closed too.

I have a 60 gallon Craftsman Professional that I bought new in 2010. I hadn’t used it much but my kids did. It locked up due to low oil level.

I bought a new pump on the ‘bay and didn’t notice that the inlet was on the wrong side. All the other dimensions were the same.

I kinda procrastinated and couldn’t return the pump. Just being honest!

Can I turn the head around to make this pump work? It is the standard 3hp two cylinder $99 dollar special. Aluminum with steel sleeves. I know, I am an idiot and baffoon! I have a smaller compressor but I would like to fix the big one to run a sand blasting cabinet.

Please don’t beat me up too bad but will this work? Thanks!

Please, in a comment, add a photo of the old and new pump and the compressor base, and on one of them identify please what you mean by “the inlet is on the wrong side”. Also, since we aren’t quite sure by what the “standard $99 special is, please provide the model number of the pump.

In easy terms, as long as you can connect everything, even if it means “creative plumbing” there is no reason why you cannot orient the pump the way you like. It just depends on how much more work you may need to do.

Can you tell me where I can get a piston rod for my 6hp twin valve oil less compressor?

If you google “pump parts for xxxxxx Craftsman air compressor (where the x’s are your compressor model number) does nothing show up?

It says the part is no longer available. What are my options if I have to replace the whole pump?

If parts are no longer available, and many after-market suppliers supply the same parts to various other compressor brands since many are made by the same original factory and private labelled, your choices are find a used one to cannibalize it, have a local machine shop make you one, or buy a new pump. Sorry.

How does the on off switch assembly go back together on a model number 919.155613 model

I posted a question regarding a stubborn check valve that I cannot remove. Does anyone have any suggestions about buying a new check valve of the same specs that I could add on between the existing check valve and the cylinder head? I have the tools for pipe bending, flaring, etc., so it would not be a problem to do that.

I have a 919-16523 5.5 hp 26 gallon compressor that comes on then shuts off b4 it builds up any pressure. Would it be the run capasator causing this problem?

Could be. Sounds like an electrical issue. Before checking the caps though, track the power from source to motor and make sure all the connections are tight. If so, then yup, check the capacitor and that info can be found here: http://fix-my-compressor.com/is-the-compressor-start-capacitor-working/

I have an older Craftsman compressor model #15658 with a stuck check valve. I have tried WD40, tried heating it, and even used a 2ft cheater pipe on an 18″ breakover and it will not bulge. Any ideas how to get it out. The valve will not close allowing the tank to bleed out through it. The unloader valve is good, every thing works good for its age.

I posted a question about a Craftsman compressor problem on the Crastman section over a month ago, but have gotten no replies. The ones before and after me were responded to, but mine seems to have gotten overlooked. I really need to get this thing up and running because I need a second compressor but cannot afford to buy another one. Thanks.

Larry, your follow up post was moved here.

Sometimes a question doesn’t get answered as there is nothing further that visitors can suggest. You’ve tried heating where the check valve enters the tank to loosen the threads with no luck. You’ve tried a breaker bar to increase torque to remove the valve with no luck. Short of trying to rig up an impact wrench to break the thread lock if that would even work, I have no other directions for you.

I appreciate that money is always an issue for most folks. Maybe you can find a similar sized compressor of another brand that’s been used and not abused, and rig the tank from that for your existing pump and motor. Otherwise, all I can say is good luck. I have no further suggestions, and so far, neither does anyone else.

I have an 07 Sears 929.167244 compressor with a dead motor, all switches good, 120v gets to motor, brushes look near new, 30ampfuse good on motor. Cannot get anywhere looking up the devilbiss D30106 motor # or ECM motor #E02645-10. Is my compressor trash for no motor replacement available?

I bought a pallet of 41 with that exact part number at auction if interested my email is pdmotley1967@yahoo.com

Michael, unless there is an in-line burnt fuse inside the motor cover that you haven’t found then I’d be of the opinion that the motor is toast too. However, don’t know why you don’t just Google replacement compressor motor of the same HP, voltage and shaft size. No rule that I know of says you have to use an OEM motor on a compressor pump.

Willyr: Thanks for the reply, the motor is thru bolted to the cast pump casting and drives a cogged belt to the pump. Only the mfg replacement would fit and I’ve come up emply on finding that. A complete pump!motor assy is available for $196 , the whole compressor was $178. Guess I’ll round file this one and get a new one. Thank for the reply

Hi, I have a 919.165610 and when I power it on the centrifugal switch is clicking constantly, it still builds pressure albeit slowly. Any help you could offer would be much appreciated

I have Craftsman compressor 25 gal. Model 919.727321 serial #2116048444.

For last couple of year compressor usually tripping breakers at cut in pressure.

I open it an discover that plastic cover/box for capacitor is broken in few places including holding bolts opening that make it very loose and vibraitin. I suspect that this may be reason for problems. On the box is yellow sticker with numbers KCR49TN2312CX. I can’t find this part anyware. Mayby somebody can direct me to right place?

Did you ever find the plastic box cover? I’ve got the same issue

Check to make sure that the compressor unloader / bleeder valve is operating properly. If it really is a capacitor that’s failing, some tips on finding a new one can be found here: http://fix-my-compressor.com/finding-a-new-compressor-capacitor/

HI, Appreciate your site and any help.

I thought my only problem was a leaky regulator. I have a Craftsman single stage 919.167770. They don’t make the exact regulator anymore and the replacement is very similar looking but the airflow is just the opposite of the original so I had to take the plug out of one side and place in the other in order to install the gauge so I could read it properly.

I would note that I didn’t originally catch this when I installed it and ran the unit but it would only build pressure to about 30 or so and then started leaking. I figured out the error and reinstalled properly————-NOW, my problem is that it builds pressure and keeps building pressure WITHOUT shutting off! Even when I put the regulator at the lowest setting it keeps building pressure! Could it be a coincidence that the pressure switch has now gone bad at the same time the regulator did?? The machine is about 17 years old with minimal use. Should I try a new pressure switch to see if this corrects the situation? Wonder if I may have damaged it somehow when I installed the regulator backwards?? Thanks for any help!!

Hi John. Are you saying that the air compressor runs past the normal cut out pressure, and keeps running until the PRV cracks open to vent overpressure? Whether or not the air regulator is set for low pressure or high, that has absolutely no bearing on when the air compressor starts and stops. The function is performed by the pressure switch. If the compressor is not stopping at the normal cut out pressure level, and the pressure continues to build, it is almost 100% certain that the pressure switch has failed.

Got a quick question- I bought a replacement pressure regulator for my craftsman model 919.167244 air compressor. Can I just replace the valve/knob assembly- looks like it just screws in or should I change the pipe and all the gauges/relief valve too- seems easier if I can just change the valve

Not knowing why you need to replace the regulator I don’t know if it is the only problem. I see no need to change the other components if they are working. If the new regulator parts don’t fit the old regulator house, then just replace the whole regulator with the new.

I have a craftsman 26 gallon air compressor just changed the valve pressure switch it turns on to 125 then it just off and when the air drops it doesn’t kick in again I have to unplug the Compressor for a few minutes I plug it back and it works for a few seconds and it dies again

Is this a new issue, Maurice, since you changed the pressure switch, or did you change the pressure switch to try and fix this Craftsman compressor issue? Can you add a comment here with the model number of the compressor, and if it is plugged into a wall socket or if you are using an extension cord or power bar?

Hi I have a 7 year old Craftsman 26 gallon 1.6 HP 160 PSI Air Compressor, The compressor works fine but loses about 40 PSI of pressure a day. I tried using the soap test but cannot find a leak anywhere. I thought it is was the drain plug but that is fine. We noticed the problem when the pump which is set to auto started turning on several times per day. Where could this unit be losing pressure.

If you did the soap test of all connections and found nothing, my thought is that it is likely the tank check valve is not seating properly, and letting a small outflow of air from the tank to the unloader valve – which is open when the compressor is off – and that’s depleting the air. Try soaping the unloader valve with the compressor off and see if you get bubbles. If so, drain the tank completely with the power off, remove, clean or replace the tank check valve.

Thank you! Now I just need to find where those parts are I am a newbie.

Bob, you don’t say which parts. If the unloader, and it’s part of the pressure switch, you’ll probably have to replace the switch. Simply Google compressor pressure switches and pick one that looks like, and has the same specs as, yours. If the tank check valve, same deal. Google compressor tank check valve and pick one that has the same appearance and same thread as yours.

Ok just replaced the regulator yesterday, checked this morning and no loss of pressure finally! Willyr thank you so much for all your help!

Happy that you’re compressor problem is solved. Thanks for visiting my site!

Thanks I found the complete regulator assembly on amazon for $40 so I just bought that. Thanks for you help I hope this finally solves my problem.

After changing the check Valve the unloader valve and now the pressure switch I finally found the leak. The leak is coming from the tool pressure turn knob. I pulled it off and air was coming from the valve. Do I need to change the tool knob valve? Sorry I do not know the correct terminology for these parts. The leak is so small and because it is under the knob it passed the soap test. Thanks for your help!

A slow leak from a pressure regulator usually means that there is a diaphragm or seal leak inside. Can it be fixed? Maybe, if you can find parts, though since a general purpose 1/8″ regulator sells normally for under $20, finding parts may cost you more. So yes, if this were mine, I’d change the regulator. Make sure if you do you install the new one with the arrow on the regulator pointing to the discharge coupler, the coupler into which you plug your air line connector.

Thanks again I will check that out. I also did buy a new pressure switch but when I received it, it had 4 ports mine also has 4 but they are arranged differently. They don’t show you pictures of the back of the pressure switch so how do you buy the correct one?

As long as you can connect the new pressure switch to the line or pipe from the tank, and it can “see” the pressure in the tank through that line, and you can connect the other accessories in any of the ports or plug an open one, and if it’s rated the same and connects the unloader the same, you’re good. If in doubt, take a photo of the switch from each side and the bottom, and use the photos to compare with pressure switches on line. There are only a few configurations and I expect you’ll find one that plumbs exactly the same.

It looks like your pressure switch has an internal unloader, and the line from the tank pressure feed is plugged into the bottom of it. Being very careful since there’s live power in there, let the compressor fill and cut out, take the cover off the switch, and see if you can feel or hear any air leaking.

I did the soap test of the entire system could not find any leaks. Here are some pictures of the pressure switch. I don’t see an unloader valve.

Thanks again for all your help! I replaced the check valve but it did not fix the problem. The unloader valve is part of the pressure switch but that is the one part sears no longer makes. I spray all around that pressure switch with the cover on and see or hear no leaks. How exactly is air escaping the tank? I would hate to spend $60 (if I can find the switch) and have that not be the problem.

If you look for a pressure switch that mounts the same, has the same unloader, same voltage, same pressure range, then it will work. You don’t need an OEM switch. Where is the unloader valve on this pressure switch, on the side? Please use a 1 part dish soap to 10 part waters, fill the tank, and coat / immerse the unloader valve with the soap solution. Are you sure there is no air bleeding out when the compressor is off? If not, time to spray the soap solution over the whole tank, if you’ve checked all the fittings and connections on the compressor with no leak visible. Let me know what you find Bob, OK?

I’m at a lose, I have a craftsman 25 gallon 1.8 hp. Originally the unit was kicking the breaker at around 120 psi. Tore down the pump and discovered a gasket missing and debree in piston and intake. Cleaned everything from new oil, all new gaskets and new reed valves. Test ran the compressor and same thing happen at 100psi. Again tore into the head and found this gasket broke in same area. This time I manually cut out a gasket with a tougher material and installed. Conducted a test run with inlet pipe disconnected for 5mins. Everything seemed to work good. Connected the inlet pipe and let pressure build up. Pressure reached 150 psi and cut off. Everything seemed to work properly other than the head unit got hot. Did a second test and compressor started at 80 psi after air was bled off. Once started it the pressure would not rise. I removed the pump tube and there was very little pressure coming from the pump. I removed the inlet filter and there wasn’t any suction. Again I removed the head and valve assembly and this 3rd gasket had failed in the same area as the last 2. I have read other post and don’t know why or where to go from here.

Brian, this compressor issue suggests to me that your valve plate has a problem with the high pressure side. When the tank pressure rises to a certain point, the high pressure valve may not be letting more air into the tank. This would cause a rapid rise in pressure inside the pump, and may lead to just the type of gasket failure you refer to. Consider replacing the valve plate.

Another think just occurred to me. Also consider removing (with tank empty) the tank check valve and giving it a thorough rinsing in solvent. Once it dries, reinstall it. If the tank check valve is acting up, that, too, could cause backpressure in the pump.

Thanks, in the future what kind of compressor do you recommend for home use?

Also do you have an email?

You are welcome. Picking a compressor is pretty much covered here: http://fix-my-compressor.com/how-to-buy-an-air-compressor/. If you wish to contact me, please do so via the contact page. Thanks.

I have a craftsman air compressor twin piston. Recently it would start running rough around 80psi to the point of dimming the lights and tripping the breaker after it continuesly ran. The top of the head would be very hot to the touch. I took the compressor apart and discovered the gasket around one of the reed valves to be missing. I replaced 4 reed valves,all gaskets and new oil. Once all new parts were installed I started the compressor up and it ran like new. Pressure built up to around 120. At this point I heard a pop and the compressor started struggling. The lights started dimming with each stroke of the piston.

I unhooked the tub that connects the compressor to the tank. Once disconnected I engaged the electric motor and pump and both ran smoothly.

I’m at a loss to why it get to the point of dimming the lights while running under pressure but runs smooth with no pressure.

Please see the page on this site about checking your compressor motor capacitors. That’s where I would start.

I have a craftsman twin cyl Mod. 919166330which will not build any pressure. I replaced the check valve and the valve plates. Where else do I look?

I would have thought that this page answers that, Bill? http://fix-my-compressor.com/compressor-will-not-build-pressure/

I’m sorry but none of my unit manuals identify a down loader valve. Only the check

valve and the safety valve are identified. Disconnecting the pressure relief tube tells there is pressure from the pump but none in the tank. The check valve is new.

Any ideas?

I an not able to identify what you mean by pressure relief tube? Are you speaking of the tube from the pump to the tank? If so, how are you monitoring that pressure? Are you able to stop the outflow by putting a gloved finger over the port? I, too, do not know what you mean by a down loader valve. If you are referring to what I know as an unloader valve, that component is important when the compressor goes to restart. The unloader comes into play when the tank pressure reaches cut out and the compressor stops. It seems as though your compressor has no problem starting, just building pressure. When the compressor is running, does the tank gauge indicate any pressure buildup at all?

Yes, it does about 5lbs. The pressure relief tube runs from the check valve to the the switch and unloader valve. If I disconnect the tube from pump to check valve I can stop the discharge from the pump with my thumb. The discharge does seem small but I have nothing to compare. This is a large compressor and I would expect more. Do you think I have a pump issue??

Yes. I would suspect that a pump kit is in order, and include in that the piston rings if, when it is running, air is venting out of the oil fill tube… assuming this model has one. I am unable to determine that.

I have a Craftsman Model 919.165110 compressor. Put in a new capacitor ( thought that was the problem)..runs for 3 seconds then trips the breaker…any idea’s??

If it runs for only 3 seconds, and it’s not the start cap, I’d wonder about the overall power supply? Can you tell us how you are getting power to the compressor, the amperage of the circuit, and what’s all on the same circuit that is feeding the compressor?

I finally found someone with the same issue I have on a Craftsman model 919.15294, even down to already replacing the start cap. It ran 1 sec on 15 amp in garage directly plugged into wall. Garage has lights, garage door opener, etc. So I tried the laundry room with its own 20 amp for the washing machine. Unplugged washer and plugged in compressor and it ran 3 seconds before cutting off. Any ideas???

Typically it’s the dryer that needs the 20 amp, not the washer, due to the drying cycle of the dryer requiring higher power supply for the heater. This issue almost always comes back to a power supply, whether it be power to the compressor, or the power circuit in the compressor.

If you are supplying the compressor with a plug in on a 20 amp supply circuit, if nothing else is pulling power from that same circuit at the same time you are trying to run the compressor, if the start and run caps are working to norm, all fuses good, then it is either the thermal cut out itself that’s failing, a short / loose connection of wires, or the motor.

Turns out it was the run capacitor which I had not checked because I thought it took longer for that one to kick in. Thanks for your help.

I do have another question you may be able to answer: the replacement capacitor I got is a little larger and doesn’t fit in the cover very well. Is it ok to use a longer screw for the cover and let the capacitor sit against the motor? Or should I try to stretch open the cover? Or just try to find another replacement? Thanks

Matt I cannot see what the original setup was. As far as the mounting goes, if the originals were in close proximity (only wondering about heat transfer) then the new, larger one, should be good. As long as the new capacitor has the same ratings as the old, it will work.

Here you can see the start capacitor cover on the right is flush to the motor but the run capacitor cover won’t go flush (the capacitor itself is touching the motor inside of fitting all the way in the cover) Thanks again.

Thanks for the pics. If the capacitor(s) were flush to the motor before, doing so again won’t hurt.

I have a Craftsman portable air compressor, Model #921153101. It will build up pressure rather quickly until it reaches about 90-100 psi, at which point, it trickles (1-2 psi per minute) up to over 100 psi. It never reaches the 125 psi cut-out, and the compressor smells like it is getting too hot so I end up manually shutting it off in fear of it over-heating. Any ideas on what this could be, or, is anyone else having similar issues as well? Thanks!

First, make sure of the power supply with no extension cores being used. Then it probably would be a good thing to check that the tank check valve is working, and then next, check the capacitors, Brian. If all is good with them, it may be necessary to tear down the pump and install a valve plate and gasket kit, as the next thing I would check is the valves.

I have a Craftsman air compressor model # 919.167812 that I am having problems with the

pressure switch. I have installed 2 and every time the cut switch/ unloader when the compressor reaches the cutoff pressure the motor shuts down and the unloader starts spewing until it reaches the cut on pressure the motor comes on and it stops spewing. If you turn the switch to the off position and the unloader starts spewing until the tank is empty. Any ideas would be helpful. The switch is an A71370.

I suspect you don’t have a pressure switch issue Randy, but a leaking tank check valve. Please see the pages on this site about how they work together with the unloader to better understand why I say this.

I have checked the tank check valve that on my compressor mounts in front of the pressure switch. When you pull it, it releases air and will quit when released.

Randy, what you are referring to, I believe, is your compressor PRV. That is not the tank check valve. Please read the pages on this site about tank check valves and how they interact with the unloader valve attached to the pressure switch.

Willy you were absolutely correct pulled the valve and cleaned it. The compressor is working properly again. Thanks for the help.

Glad to have helped.

In my 60 gallon, 3.1HP twin cylinder oil lubricated 150 psi compressor, the motor has failed. It was working just fine and now won’t start.

Taking off the panel on the motor itself, I can measure 240VAC inside the motor which turns off when I switch off the on/off switch on the pressure switch.

The only circuit that is inside the motor that could be keeping it off is the thermal shutdown cutoff. That button is not out / cannot be reset. Is that a common part to fail?

The motor’s capacitors look intact as well.

Any idea what could be wrong?

The thermal reset or cut out switch is just that, a switch. If you probe both sides with your meter you can tell if the switch is passing. If it is not, given that the motor is cold through none use, the thermal cut out could have failed. If it is passing power however, I would be inclined to actually test the motor cap, not just see if they “look good”. Make sure you check the cap connections as they do sometimes vibrate loose.

Hi – I have a three year old craftsman 33 gallon vertical compressor model 921.165720. rated to 165 psi. Problem started last year and Sears will not service the unit for some reason – at least my local one wouldn’t.

From what i could find last year and still holding true this year, the unit runs to about 80 psi and shuts off. They only way to get it back on and continue is to unplug it from the outlet and wait. The longer it ran, the longer i have to wait. What i have read was this is a thermal switch causing this to happen, thus the removal of power completely is required to reset. Eventually I can get it up to about 130 psi. Is this fixable? I only use this about 3-5 times a year, so as you can imagine I am quite upset with this Craftsman product. And the outside outlet is direct to panel, so there is nothing on the circuit but the compressor. Any insight would be great. Thanks. Scott

Just wondering if you are using an extension cord or not, Scott? Try plugging the compressor into a circuit with nothing else on it, preferably a 20 amp breaker or fuse. Does that make any difference. From what you have written I suspect either a failing run capacitor which would cause the motor to run hot, and go off on thermal. That it is going off on thermal cut out isn’t a bad thing, and does not necessarily mean that the thermal cut out switch has failed. See the page on check the capacitors on this site too.

Thanks for the reply. The compressor is plugged in directly to outlet – no extension cord – and this is the only outlet on the circuit breaker (know for sure as I installed it to support Christmas lights). Problem is it take 30 mins or so of plug, unplug, plug, etc to get it filled once, Do that over 3 zones for a sprinkler and what should be a nice quick winterizing takes 4 hours or more. Very frustrating.

I’m still guessing the start cap.

Hi, I have an older 6 gal. Sears model: 919.165281 oil-less pancake, it has no un-loader valve on the (mechanically controlled / electrical contact) pressure switch (AC-0747) 110 on – 135 off.

From what I have read in the forums here, it is not necessary, since it is small.

However, it seems apparent to me that I should be able to replace the mechanically controlled contact pressure switch with an electrical one (e.g. VA811502PF or N003307SV or similar) with the same or close to the same cut in and cut out limits. Please correct me if I am wrong. (PS: I know they are both mechanically controlled via air pressure, it’s just for the sake of differentiating the two kinds of switches) the original (hard wired) is much larger, than the ladder type with two wires molded into it or terminals for connectors.

Also, I would like to know, at what point, of air pressure or type of compressor do I need to concern myself with a compressor that should require or have an un-loader valve?

Thank you for your time and attention.

Even though this is a small air compressor, we’d be willing to bet there is an unloader of sorts. If you pull the shroud and look at the line from the small compressor pump to the tank, can you spot a small hole? That’s the unloader. When the compressor stops, this small hole bleeds all the air out from over the piston. That it also bleeds air while the compressor is running, wasting air and electricity, is also a fact… if you find the hole.

I have a craftsman 26 gal oil free direct drive air compressor model #921.64710. it builds pressure up to about 80ish (pretty consistent) and then cuts out. if I let it sit for awhile and turn it back on it will continue to build air and finally reach it max PSI of 150 but does not cut back on after pressure drops from use. I attempted to test the capacitors and if I did so correctly thy are ok. I tested the power out put into and out of the pressure switch and have power to the motor even after it cuts out. This will be my first compressor repair and I have done my best to research the problem but am still at a loss. do you think this is thermal overload problem that requires a new motor or hopefully something I have missed?. thank you in advance.

That you checked to see if power is still passing the switch or not when the compressor cuts out suggests that the problem is NOT the pressure switch. That brings us to why it’s cutting out at all? If it’s not the switch, then it’s got to do with the power supply to the motor, or the motor itself. What we don’t know is if there is a compromised power supply. The use of a too small extension cord, or a number of other electrical appliances pulling power from the compressor supply circuit could be at fault. A capacitor that overheats may cause this though you say that yours are fine. That points to the motor then, and that could be brush wear, weak and mildly shorting windings on overheat… a number of things. If all other things are OK, then it’s time for a motor check at a motor repair shop. You do want to make sure that you don’t run the compressor more than it’s duty cycle. If you don’t know that, then don’t run it for more than 10 minutes without allowing at least a 10 minute off time for the compressor to cool down.

I have a craftsman compressor, 20 gal, 220 volt with 2 piston pump.the loader valve on the regulator was always leaking causing the compressor to kick on and off. I replaced the regulator and the new one leaked. Found the tank check valve was faulty , I repaired that and now when the compressor is running it sounds like it’s missing a beat every so often. can you tell why? Thanks AL.

Al, like to help, but really we cannot hear what you mean by missing a beat. Hopefully someone our there is experiencing the same Craftsman compressor problem and can offer a solution. Good luck.

I have a craftsman 80 gal. Compressor runs but will not go past 50lbs sounds like I’m hearing air coming from some where but not sure what to check. Thanks in advance for your help

These compressor issues are covered on a number of pages on this site, Tommy…

http://fix-my-compressor.com/compressor-always-leaking-air/

http://fix-my-compressor.com/compressor-leaking-air-under-the-hood/

http://fix-my-compressor.com/compressor-will-not-build-pressure/

… to show just a few.

Please have a look, do the checks, and add a comment here with your findings if you still need help.

I have a Sears compressor model 106.153780 it’s a pretty old compressor. The issue is, when the compressor reaches 70psi the compressor pump seems burdened then the motor bogs down. I quickly shut off the breaker to avoid and damage.

So far I’ve checked:

Pump oil – full

Check valve – Ok (air goes to from pump to tank and not vice versa)

Flappers – seem ok and operating

Any other ideas?

Good that you’ve checked the things on your Craftsman compressor that you have. Assuming a good power supply, no intake filter blocked, the pump sheave turns relatively easy, the next check would be the start / run capacitor. Some have one cap, some compressors have two. Check ’em all.

Ok, so I’ve gotten the first issue fixed. It was the check valve. I filed the ring impression out of the valve and extended the spring adding more tension to the valve. I replaced the electrical cord adding a new plug and replaced the brittle cord from the motor to the switch. The compressor now runs and shuts off normally however it shuts off at 60 psi. When in use it kicks on and off normally but only develops the 60 psi. everything else seems pretty normal. I’d like to develop at least 100 psi. although the compressor is rated for 150 psi. what can I do next?

Good on you for the work on your compressor, Dan. Okay, next question… when the compressor shuts off at 60 PSI, is there power on the motor side of the pressure switch? You’ll need a meter to check… carefully please. If there is power on the motor side of the switch and the compressor is off, then the switch is likely OK, and that points to the motor as being the problem. What did you find?

Hi, I have a Craftsman Model # 919165220 20 gallon single stage.

It seems to run and fill up fine but occasionally will give a loud high pitched squeal while running. I’ve noticed it’s more likely to do it after the tank has been completely emptied and the pressure passes 30psi as it refills. I’ve tried to pinpoint it with a mechanics stethoscope with no luck. I’ve ruled out any loose fasteners or fittings.

The strange thing is that I can make the squeal go away by pushing on the pump, tank, handle or pretty much anywhere on the compressor. Even a light tap on the cover will make it stop for a few seconds.

Can the valve plate cause this type of sound?

If I pull it will a visual inspection confirm a problem?

First off, yup, a gasket leak or valve plate flutter might cause the noise. However, if the compressor is working fine otherwise, and the noise is not too intrusive, eventually what’s causing the sound may ultimately give up the ghost, and then you are into compressor repair. Since you cannot see sound, pulling the pump apart to check may not be productive. However, if there are other symptoms, it does sound (pun intended) that your compressor might do with a rebuild kit, which should include valve plate(s). Make sure to replace any gaskets as well, as we think that an at-certain-pressure gasket leak may be the origin of the sound.

Thanks,

The noise is very loud. Not bearable for long. I’m going to open it up and see what the valve plate looks like. A new plate isn’t too much.

I’m not getting the feeling like it’s a bearing. I sprayed some lube on the crank joints with no effect. In my experience as an auto mechanic, a shot of lube will temporarily quiet a noisy bearing enough to make a diagnosis. This just seems like some strange resonance that comes and goes.

I have a Craftsman 3 gallon 1 hp air compressor bought in 2007. Just used it this morning and went to turn it on again and only heard a clicking sound from the switch box, I believe it is called the pressure switch. I release the pressure after every use. Can I repair this myself or bring it to Sears for repair? If it is worth it.

Bob, sure you can fix it yourself if you are handy. Is it worth it? Depends on the repair cost versus new, we guess. If you see this page it will offer some further guidance: http://fix-my-compressor.com/clicking-air-compressor/

I have a craftsman 919-164180 that starts but stops immediately i took it apart and put it back together and it turned on twice then started acting up again. I had the stop/start capacitors checked and they tested good although one was kinda warm. Any thoughts?

When the compressor stops, is the pressure switch still passing power to the motor circuit? In other words, it is not the pressure switch tripping off prematurely that is shutting the compressor down, even though the tank pressure is not yet at cut out?

I have a crafstman model 919137670 compressor. The compressor is not automatically restarting. The intial start will fill the tank to 120 PSI. Regardless of the device that I use once the PSI drops below the recommended PSI for that device the compressor will take about 5-10 minutes before it restarts. I have already replaced the air compressor check valve model # A19718 due to the motor not restarting once the PSI drops below the set PSI level.

We believe that the answer to your compressor problem can be found here: http://fix-my-compressor.com/compressor-wont-re-start-when-air-is-used/ , and: http://fix-my-compressor.com/compressor-trips-the-breaker-when-the-pressure-drops/ .

Hi, I have a Craftsman Twin Tank air compressor. When I turn it out, the pressure can only build up to 40 psi, it doesn’t go any further. Can you please guide me how to fix it? Thanks.

Sure Chris. It’s pretty much all covered here: http://fix-my-compressor.com/compressor-will-not-build-pressure/.

Thank you Willy!

Can anyone help me with my 6 hp 30 gal 120v Craftsman oil-less single cylinder compressor?

Every time I use it, the surge protector I had it hooked up too would always trip every time the compressor would reach cut out pressure. When I plug the compressor directly to the wall socket without the surge protector, the circuit breaker would trip once compressor hits cut out pressure also. Any help would be greatly appreciated!

We suspect you’ve got a faulty pressure switch, that somehow is shorting out when the compressor reaches the cut out pressure setting and the pressure switch tries to switch the power supply to the compressor motor off.

Actually i just took out my compressor out of storage, plugged it to a wall socket, turned it on, and checked to see if it would repeat the problem. i have not yet changed anything on the compressor yet. as of right now, the compressor did not even reach cut out pressure. the cut out pressure for my switch is set to 135psi, my compressor stopped working and tripped the circuit breaker at 90psi. im assuming at this point my pressure switch is functional at this time. thank you for the quick reply!

What could cause this to happen? I am at a loss

There are a number of reasons, Juwan. Please look at the troubleshooting pages on this site that have to do with air compressors tripping breakers, blowing fuses, etc. After doing so, comment with what you have checked, if you will.

I have a craftsman compressor model919.167240 it continualy goes on and off . the switch seems to fine. while looking at it while pressure is building, the switch does not dissengage but the motor will stop. then it will start again. different amounts of time but it constantly does this. Anyone have any ideas?

When it stops, how long is it before it starts again? Good that you checked to see if the pressure switch was tripping on and off. If it’s not, then that points to, perhaps, the motor overheating a bit and going off on thermal cut out. Overheating could be caused by using it too long at one time, an insufficient power supply (too long or too small extension cored) or perhaps a capacitor failing.

I have a Craftsman twin cylinder compressor model 106.152581 that lately has been spitting oil out of what I believe to be a breather hole in the bearing cap. This cap is on the same side of the compressor that has the pulley. From my own online research it looks like it could be the cylinder rings. These rings are no longer available on the Sears Parts Direct website. My question is could the problem be something else and if you suspect the rings, were else may they be available? Otherwise the compressor runs fine.

Thank you

We are not quite sure how air would be blowing oil out the cap. A check on line shows that this bearing cap has a bearing gasket and an oil seal. If either were damaged that might account for the oil leak. These parts are available on line. We would replace these first and see if the problem was resolved before considering tearing down the pump to check the piston rings.

I have a good one for you… I have an old Craftsman 2 cylinder compressor. At least 40 years old. It originally had a 1hp motor (according to the sticker). It used to have intermittent issues with restarting (centrifugal switch wouldn’t unload) and it would pop the breaker occasionally. Recently it got worse.

I have:

1. Rewired with new 12 gauge cord.

2. Replaced the pressure switch (including unloader valve).

3. Replaced the belt.

4. Cleaned and tried to adjust the centrifugal switch.

5. Replaced the motor.

The original motor on this unit was a 1hp. At some point, my Dad apparently replaced it with a Century K56, 1/2 HP, 3450RPM. When I discovered this, I thought “AHA!” and that I’d be in great shape with a new motor. Sears web site called for a Century CP1152L, 1.5HP. The 1.5 is same rotation, same frame, same RPM. So I bought one. Even worse starting than the 0.5 HP motor.

This compressor has a 1/2 inch line from the compressor to the tank and a 1/8 line from the head to the unloader. I disconnected the unloader line at the head. There is no leaking from the check valve. When I fill the tank to 100LB, I can get the thing to start if the unloader line is disconnected. I can then cover the port with a rag and my thumb and it runs just fine.

The only things left to replace are the check valve and the compressor piston assembly. The pump seems to turn by hand just fine. It’s so bad now that if there’s more than 20PSI in the tank it stutters and pops the breaker.

So could a faulty check valve cause issues with starting up? Valve isn’t leaking… could it be sticking and not wanting to open?

Hi Dave. Lots of work refurbishing the compressor. Sorry that you are still having a problem. We doubt that it’s the check valve at fault, however, it never hurts to do a quick check. See a guide on this site. If you had not changed the motor (presumably with new capacitors) we would think that a failing capacitor might be at fault.

It might be the power supply. If the problem is a new one, it likely is not the power supply, as if that were the problem, the compressor would never have started earlier. Unless, of course, you’ve added other appliances to the same circuit that pull a lot of power?

New motor, new caps, decent power supply… considering all of that, it points to the pump as the issue. All other things being good we’re guessing you might have a problem with the pump valve, probably on the high pressure side, that blocks the flow to the tank when the back pressure reaches the 20 PSI.

Very informative, interesting, and practical for diagnosing and repairing air compressors. I have a free 15 gal 3 hp Craftsman compressor that is not working and would really like to get going and use for years to come. We live in a throw away society these days and will only get more pronounced with time. I love to be able to service and repair used/older equipment and know that some sweat equity , patience, and knowledge can be rewarding and go a long way in life. Thanks again for your help. Mike

i have a craftsman 919.167241 it builds up to about 40-45 lbs of pressure and keeps running but wont build any more pressure . i have to shut it off manually but it holds pressure with out leaking down. where should i start looking for the problem?

Hi there. The reasons are pretty much covered here: http://fix-my-compressor.com/compressor-will-not-build-pressure/ .

Maybe you could add a comment telling us what you found when you did the checks?

First of all – Fantastic WEB site! I’m in the middle of my first compressor repair on my Craftsman 20 gallon.

Pretty sure, based on all the articles, my check valve is leaking, since my unloader valve is leaking air now after shutdown. Its been a very slow leak for months, as my compressor (normally left on overnight) would suddenly start up for no reason and fill the tank back up.

My check valve is exactly like the one pictured, and my whole compressor layout is identical to the photo.

So I have two questions that, despite reviewing every article, I don’t see addressed.

1. What is the best tool(s) to back out and reinstall a check valve like the one pictured? Stardard channel lock pliers is the only tool I could get to work without damaging the two threaded outlets. However, I’m not completely hopeful I get it tightened enough when I reinstall.

2. I’ve read in several places about cleaning the check valve, but no where have I found exactly what that means as far as technique. I’m a pretty seasoned home-mechanic, and I have the luxury of owning a small ultrasonic cleaner. I put my valve in the cleaner for a couple of hours, but haven’t done anything else so far. I does have the plastic valve pieces inside, so I was going to lubricate these parts with a synthetic oil that is a highly purified clear lubricant designed for dental equipment. Will this be ok?

Thanks for any and all responses and help!

Mike

Mike, thanks for your kind words. To remove the check valve, first use the PRV or tank drain to void ALL air from the system. Remove the two lines. Use an appropriate sized wrench on the wrench flats (no, not normally channel locks – we prefer sized wrenches or next best a good combination wrench) to turn the fitting out of the tank. The check part of the valve is typically a ball or flap and debris gets into the seat area and prevents the ball or flap from closing tightly. Start with a really good rinse with warm soapy water. If that doesn’t do it, rinsing it with mineral spirits (varsol like) will help, with appropriate care. Last, replace the whole thing if you cannot get it to stop leaking.

Hello, I have a craftsman 30 gal. air compressor item number 919.167310. It never reaches the cut out pressure and shuts off. It reaches 80 p.s.i. and, though it is still running, the pressure will not rise above 80 p.s.i. I have no leaks, the tube to the check valve get significantly hot (maybe that’s normal given where the other end connects on the motor/piston). Can you give me any ideas what may be wrong? Thank you…

Charles, we think you will find that you have a pump problem. This compressor has what we call a mini-pump, pulls air in through a hole in the top of the cylinder we believe, and that your compressor runs on but won’t build past 80 PSI suggests the problem is valve, seals or gaskets. These topics are covered in detail on the pages of this site. Please have a look.

I have an old 919152940 that wont build pressure in the tank. The regulator dial will build to just shy of 20 psi but the tank pressure never moves. Any suggestions?

Your 919.152940 shows 20 PSI on the gauge and the tank gauge shows zero? OK, the regulator gauge may only be displaying the pressure setting it’s been dialed to. The tank gauge should show a pressure level, and if it isn’t, then we would suspect that the gauge itself is pooched. Pull the plug, dump all tank air, and then pull and replace the tank gauge or, if they are the same size and thread location, swap it for the regulator gauge and fire up the compressor again. What happens?

My Sears Craftsman compressor is about 4 and a half years old, model 921.153101. After operating it for a short time, I lose pressure to the hose. The gauges show compression but if I remove the hose there is no quick release of air. If I push the hose back into the quick connect, pressure returns to the hose but only briefly. Any ideas as to what the problem is???

We were not able to find a photo of your 1 HP or 1.5 HP compressor on a 3 gallon tank in order to see the regulator set up. Regardless, the symptom you write about, losing air flow to the hose, are ably covered on this page on this site: http://fix-my-compressor.com/compressed-air-will-not-come-out-of-the-air-hose/ .

If you would have a look at this page and relate it to your compressor, we suspect you’ll resolve this Craftsman air compressor problem.

I ran my Craftsman 4 gallon air compressor 1 HP, without oil for about 15 minutes. Now when I turn it on it just hums for about 4 seconds and then shuts down. Did I cook the cylinder and should I junk the machine? It was almost new. Mike N

It’s hard to give a specific answer without more details, Mike. You don’t indicate your model number so we don’t have any idea what Craftsman compressor you are referring to. If you can access the motor shaft by removing any shroud, and can check the drive, see if you can rotate the pump sheave, if there is one, by hand. What you are trying to determine is if the overheating your compressor probably underwent has expanded the piston or misshapen the cylinder to prevent the piston from moving. Check that out, and please add a comment here with what you found.

I have an old Sears air compressor, 1hp 12 gallon tank model 919.176311. I got from my uncle after he passed, and it worked fine for the past few years, but the other day I went to use it and the motor was just clicking, after a while I tried it again and it will start up like it supposed to but in about 20 seconds it trips the circuit breaker. Its a 20 amp breaker with nothing else running on it, its plugged directly to the outlet, no extension cord. Is the motor on it going out, or could it be one of the capacitors?

We think you might have nailed it. If we were working on this Craftsman (Sears) air compressor we would certainly check the motor capacitors. If you haven’t found it, there’s a page on this site with how.

I am trying to rewire an older craftsman 220v compressor 106.174841. The motor has only two lines and I don’t see a ground screw on the pressure switch. How do I connect the 3 wires from the plug to a motor with two wires via a switch with 4 terminals?

Thank you for your help

While we have no problem tearing down and rewiring our own compressors, we are not certified electricians, and cannot provide electrical advice. We are happy to post this in the hope that someone that is an electrician will provide the information for you.

I figured I wouldn’t be able to get far. Thank you for reviewing my question and getting back to me

Stay tuned. I expect someone with electrical experience will provide advice.

Hello,